The shooter lane consists several parts:

- The lane itself with the groove to center the ball to keep it aligned with the shooter rod.

- and the shooter lane cover, that stops the ball rolling back. It also has some scale to help the skill shots.

- Sometimes the shooter lane also has a auto shooter, that can launch the ball without used intervention.

- And the shooter rod itself

|  |

The amount of power the ball receives from the shooter rod depends on several factors:

- Of course the amount the shooter rod is pulled out.

- The strength of the shooter spring.

- Less obvious is the distance between the ball and the tip of the shooter rod.

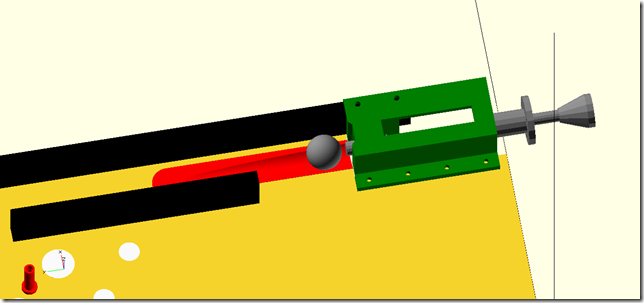

You can see in the two picture above that this distance varies. In the left picture the shooter tip protrudes the cover, when on the right it is below the shooter cover ball stop. The playfield in left picture can only be lifted, after the shooter rod is pulled back.

Firepower

I recently played for the first time on a real Firepower pinball. I also took some measurements of the shooter lane dimensions.

The wooden side rails are 14x30mm. The space between them = width of the shooter lane is 35mm.

The out- lanes are 30mm wide.

Design

Shooter lane

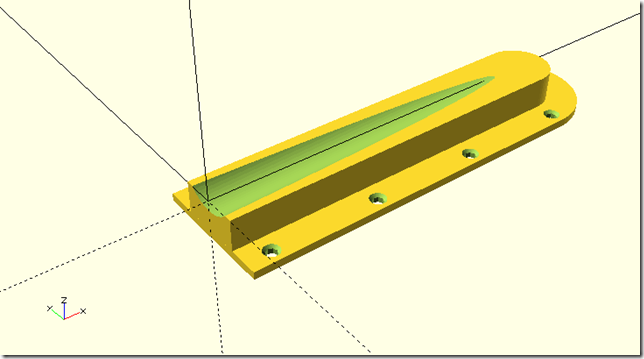

To simplify the creation of the shooter lane groove, I created an special insert for it. The original idea came from here: Swinks design http://www.thingiverse.com/thing:608164 for a shooter lane insert. The design seems to be no longer available on thingiverse. This design was on the top face of the playfield.

The shooter lane insert I designed protrudes through the whole playfield. It is mounded on the back of the playfield with multiple screws. The drawback is that the playfield looses a lot of strength, due to the large hole needed to place the insert. Part of the lost strength is taken over by the insert itself. Let us hope the lost strength is not causing issues.

Top view. The holes for the screw have some extra clearance to allow for a little bulging of the playfield wood, then a screw in screwed in. The top is rounded off, to allow it to be make using a 25mm wood drill.

The bottom of the insert contains holes for both the contactless ball sensor and RGS leds. The Leds allow some animation to be shown during game.

The left hole is for the contactless sensor, and the other ones are for the LEDs. The sensor hole is quite deep, so the sensor is very close to the pin-ball. The LED holes have a conical shape, both to allow simple 3d printing as well as to spread the LED’s light around.

Shooter cover

The shooter cover has two main functions:

- Stop the ball from rolling back, when the shooter is pulled.

- Scale to indicate how far shooter is pulled back.

The shooter covers are normally make from metal, but i designed it in plastic. The risk using plastic is that when the ball falls back that it could crashes quite hard back, and then possible break the plastic. The metal one is better, because that just bends and releases the energy back. So the plastic cover has to be quite strong at the ball side.

For the rest it looks the same as the metal version.

Possible I going to change the round woodscrew holes to oval ones, to allow a bit of adjustment relative to the rubber tip of the shooter rod. The shape is designed to it can be printed with a 3D printer. The shape is designed to it can be printed without support, when standing on the ball side.

The front where the ball can be hit is made quite thick. Also shown the extra support at the side to absorb the forces better.

Assembly views

Some views how the shooter and cover are aligned together.

The shooter lane insert is mounted below the playfield, and the cover above it.

The ball is positioned at the end of the shooter lane insert, and rest against the shooter cover.

Bottom view

Here is the shooter lane insert and cover projected to the playfield.

Other view without the cover.

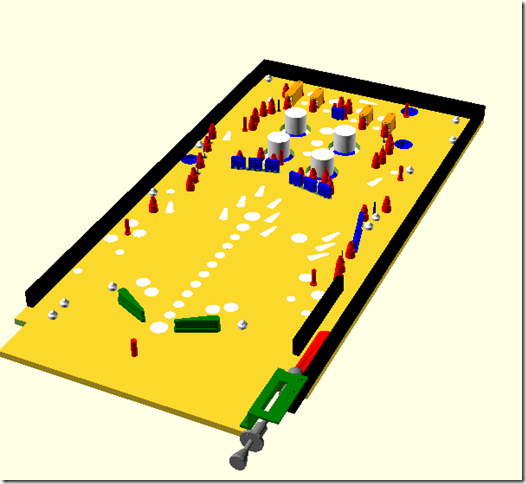

The full view of the playfield.

In a later blog will go into more details how this picture is created. This view is still missing lot of parts, like all the ball guides , pop bumper , slingshots and ball trough. These are still in development.

Result

I only have printed the insert at the moment.

Here the top view of the insert.

The bottom view. On the left the inductive ball sensor holder. The 3 screw pairs on the right are to hold the small WS2812 RGB LED PCB’s. You can see the honeycomb fill pattern used during 3D printing.

![cover_t[4] cover_t[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEg1Go7bl1PXvieXrwd9m0ubPmiL9T5-Zn9Rcu6MvwdFjUuiEe6JZCa0Yr5bj-01Ad87BDD8FjpGjlKx-M_sJdsaiklA3LZk2aF8SwIEijlUTt8V0qxy0qFCtb1nYKJwuImnexO5HN_2aQ/?imgmax=800)

No comments:

Post a Comment